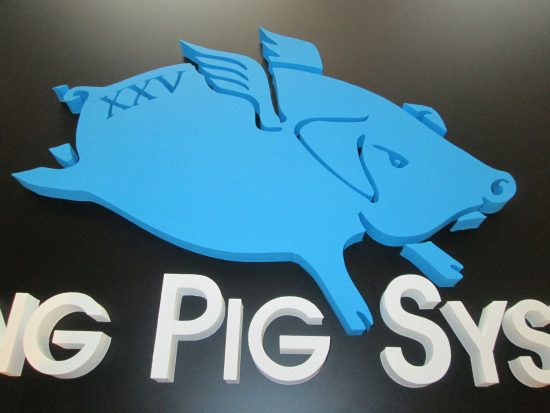

Office wall logos and business reception logos made from painted styrofoam.

Looks great in any office or reception. Mounted onto the wall with either VHB tape or contact adhesive for permanent or temporary wall displays.

Office wall logos and business reception logos made from painted styrofoam.

Looks great in any office or reception. Mounted onto the wall with either VHB tape or contact adhesive for permanent or temporary wall displays.

Shop display letters and shop display logos made from styrofoam and polystyrene. painted in a vinyl matt emulsion to match the customers requirements, matched to pantone or RAL colours.

Window displays

Shelf Displays.

Ceiling Hanging Displays.

Animal profiles of eagles and dragons for shop displays. Up to 600mm high. Examples show 100mm thick polystyrene shapes 600mm high.

3D letters logo made from painted styrofoam to the customers pantone colour match.

Styrofoam logos can offer several benefits for exhibitions. Here are some advantages:

Lightweight: Styrofoam is a lightweight material, making it easy to transport and handle during exhibition setup and teardown. This quality allows for flexibility in placement and reduces the risk of accidents or injuries during installation.

Customizable: Styrofoam can be easily shaped and molded into various designs, making it highly customizable for creating unique and eye-catching logos. It can be carved into intricate details, giving a professional and polished appearance to the exhibition display.

Cost-effective: Styrofoam is relatively inexpensive compared to other materials commonly used for signage and logos, such as metal or acrylic. This affordability makes it an attractive option for businesses or organizations with budget constraints.

Versatility: Styrofoam logos can be used both indoors and outdoors, as the material is weather-resistant and can withstand moderate exposure to elements like sunlight and moisture. This versatility allows for consistent branding across different exhibition environments.

Easy to install: Due to its lightweight nature, styrofoam logos are typically easy to install and remove. They can be attached to walls, backdrops, or display stands using adhesives or hooks, providing convenience during exhibition setup and allowing for quick adjustments if necessary.

Enhanced branding and visibility: Styrofoam logos can significantly enhance your brand’s visibility at exhibitions. Their three-dimensional design and vibrant colors make them stand out, attracting the attention of visitors and creating a memorable impression. This increased brand recognition can lead to improved customer engagement and potential business opportunities.

Reusability: Styrofoam logos can be reused for multiple exhibitions or events, making them a cost-effective long-term investment. With proper care and storage, they can maintain their quality and appearance over time, allowing you to maximize their value.

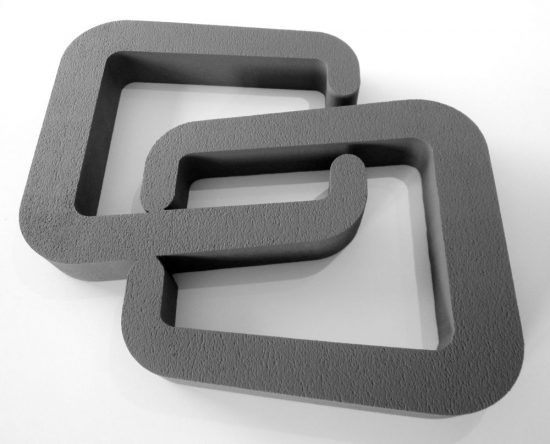

Faux concrete signs made from styrofoam are a popular choice for many applications. They offer the appearance of real concrete but are much lighter and easier to handle due to their construction from styrofoam.

To create faux concrete signs from styrofoam, here’s a general guide:

Materials needed:

Instructions:

Remember to follow safety guidelines when working with tools and materials. It’s also essential to check local regulations for any restrictions on using styrofoam or the type of paints and sealants you plan to use.

Creating faux concrete signs from styrofoam is a creative and cost-effective way to achieve the look of real concrete without the weight and expense.

Faux concrete sign made from styrofoam, coated with a 2mm layer of grey limestone acrylic resin mix textured masonry finish. Made for short term outside use at a university campus.

The sign measured 3300mm by 450mm by 50mm thick.

The faux concrete sign concept was initially created for use on interior wall logo displays, used by various building and construction companies as well as interior designers and hair salons.

By using the correct glues and resin the signs become suitable for outside use. If we increase the amount of limestone resin coating on the styrofoam, the panels become even more durable and suitable for long term use outside. They would also make a good base panel for painting art panels or for sign writers who are looking for a masonry finish.

We have been working on coating the panels in sandstone, yellow limestone and grey limestone.

Using the stone resin coating method we have also been producing faux concrete letters for interior free standing office displays and for use for commercial photo shoots.

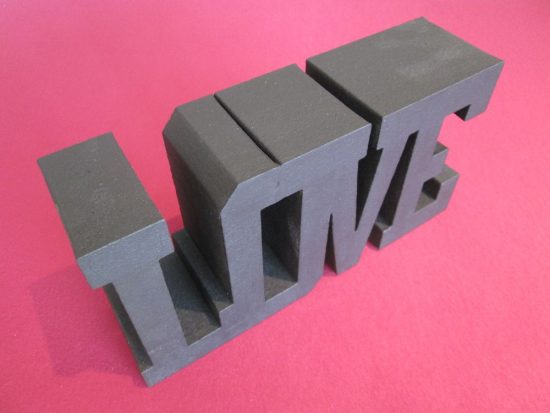

3D love text, connected love letters, painted grey. Supplied for shop displays. Made from XPS foam.

Styrofoam logos refer to logos or branding elements that are created using expanded polystyrene foam, commonly known as Styrofoam. Styrofoam is a lightweight and versatile material that is often used for packaging, insulation, and crafting purposes. It is composed of about 95% air, making it an excellent choice for creating large and intricate logo designs.

Creating Styrofoam logos typically involves a process called CNC foam cutting. A computer numerical control (CNC) machine is used to precisely carve and shape the Styrofoam material according to the desired design. The machine follows a digital template or design file to accurately replicate the logo’s shape, curves, and details. This process allows for the production of logos with sharp edges, intricate patterns, and complex three-dimensional designs.

Once the Styrofoam logo is cut, it can be further customized and finished based on specific requirements. Some common techniques include:

Styrofoam logos are commonly used in various settings such as trade shows, exhibitions, retail displays, signage, and corporate events. They provide a lightweight and cost-effective alternative to heavier materials like metal or wood while allowing for intricate designs and customization options.

Free standing office desk logos. Made from painted styrofoam.

350mm high, 100mm thick.

Styrofoam desk logos, also known as foam desk logos, are customized branding elements that are made from expanded polystyrene foam (commonly known as Styrofoam). These logos are designed to be placed on desks or other flat surfaces to promote a brand or company.

Here are some key points about Styrofoam desk logos:

Painted styrofoam letters and logos for office walls and office events.

Painted Styrofoam logos are commonly used for shop displays for several purposes. Here are some of the main reasons why businesses use painted Styrofoam logos for their shop displays:

Overall, painted Styrofoam logos offer businesses a cost-effective, customizable, and visually appealing solution for shop displays. They contribute to brand recognition, attract customers, and enhance the overall aesthetics of a store, helping businesses effectively showcase their brand and products.

Metal faced polystyrene letters, copper faced polystyrene letters made from copper foil laminated onto a rigid card mounted onto polystyrene for use on office walls or retail outlets for visual advertising.

Faux metal letters made with a metal foil face onto polystyrene or styrofoam available in brushed copper, brushed aluminium or polished aluminium.

Copper foil faced polystyrene letters are three-dimensional lettering made from polystyrene foam with a copper foil covering. These letters are commonly used for signage and displays, particularly for indoor applications.

Polystyrene foam, also known as expanded polystyrene (EPS), is a lightweight and versatile material that is easy to shape and manipulate. It is often used for various crafting and construction purposes due to its affordability and ease of use.

Copper foil is a thin sheet of copper that can be adhered to different surfaces for decorative purposes. When applied to polystyrene letters, it provides a metallic and reflective appearance, adding an attractive and eye-catching element to signage and displays.

Copper foil faced polystyrene letters are typically created by cutting out letter shapes from polystyrene foam sheets and then applying a layer of copper foil to the front of the letters. The copper foil is usually adhesive-backed, making it easy to attach to the foam surface.

These letters can be used for various applications, such as in-store signage, trade show displays, event decorations, and more. They offer a visually appealing and professional look while being lightweight and easy to handle.

It’s important to note that while copper foil faced polystyrene letters can provide an elegant appearance, they are primarily intended for indoor use. Exposure to harsh weather conditions or excessive moisture may damage the foam and the copper foil, reducing their lifespan.